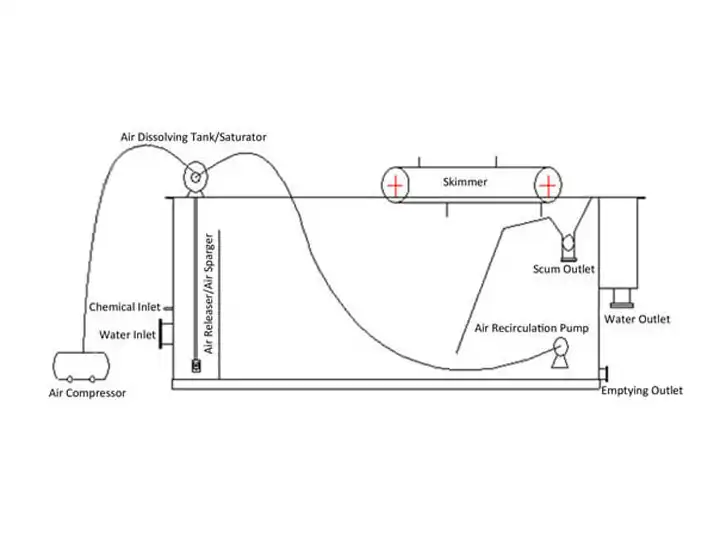

Here we describe dissolved air flotation working principle, for the componnents' names and photos mentioned in these below, please refer to article: Dissolved Air Flotation Filtration.

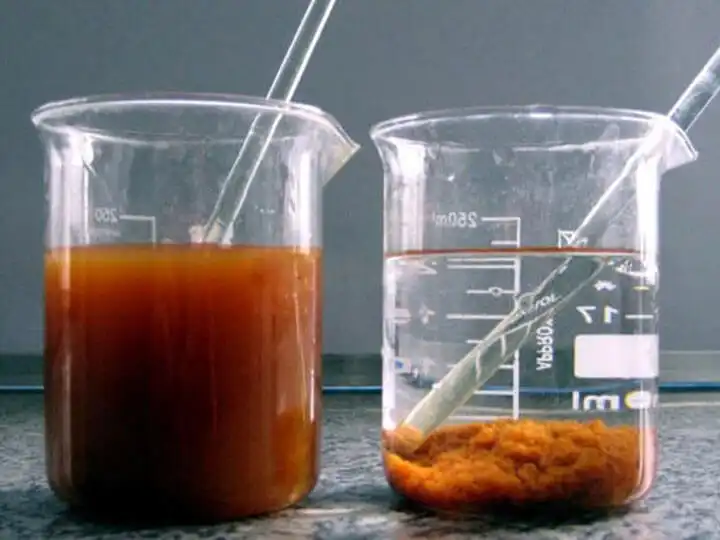

The feed water to Dissolved Air Flotation is often (but not always) dosed with a coagulant (such as ferric chloride or aluminum sulfate) to coagulate the colloidal particles and/or flocculants to conglomerate the particles into bigger clusters.

A portion of clarified effluent water leaving the DAF tank is pumped into a small pressure vessel (called air saturator) into which compressed air is also introduced. This process saturates pressurized effluent water with air under pressure 4-5kg/cm2.

The air-saturated effluent water is recycled to the front of air flotation tank and flows through a pressure reduction valve just as it enters the front of air flotation tank.

This immediately results in the recycled effluent water becoming supersaturated with air as millions of tiny bubbles form(Φ5-20μm).

These bubbles attach to, and form within, the solids or chemical flocculants entering the vessel, causing them to float to water surface where they are retained and subsequently removed by a skimmer.

The separated scum will be collected to the Scum Trough and be discharged through the Scum Outlet. Treated clean water then flows through an adjustable overflow weir and is discharged through Water Outlet.

Contact: Eng. Dover

Mobile: +86 17561675721

Whatsapp: +86 17561675721

QQ: 1049235017

Wechat: 1049235017

Email: dover@cnwwtp.com

Addr: Beiling, Machang Vil.

City: Qingdao, China.